Biochar has emerged as a powerful tool in sustainable agriculture and carbon sequestration. Produced from organic biomass through a thermal process known as pyrolysis, biochar offers numerous environmental benefits — from improving soil health to capturing carbon in a stable form. Understanding how this black, carbon-rich material is formed helps explain why it has become a crucial part of global carbon management strategies. This article explores the step-by-step process of biochar generation, focusing on the essential equipment involved in pyrolysis.

Understanding the Biochar Machine

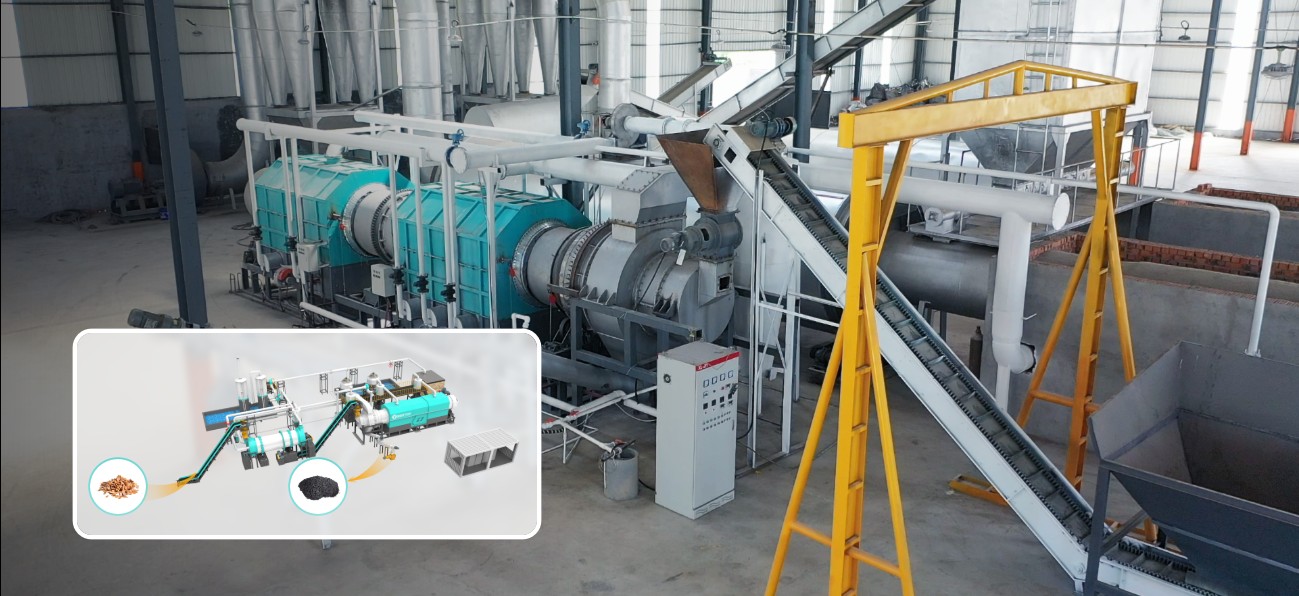

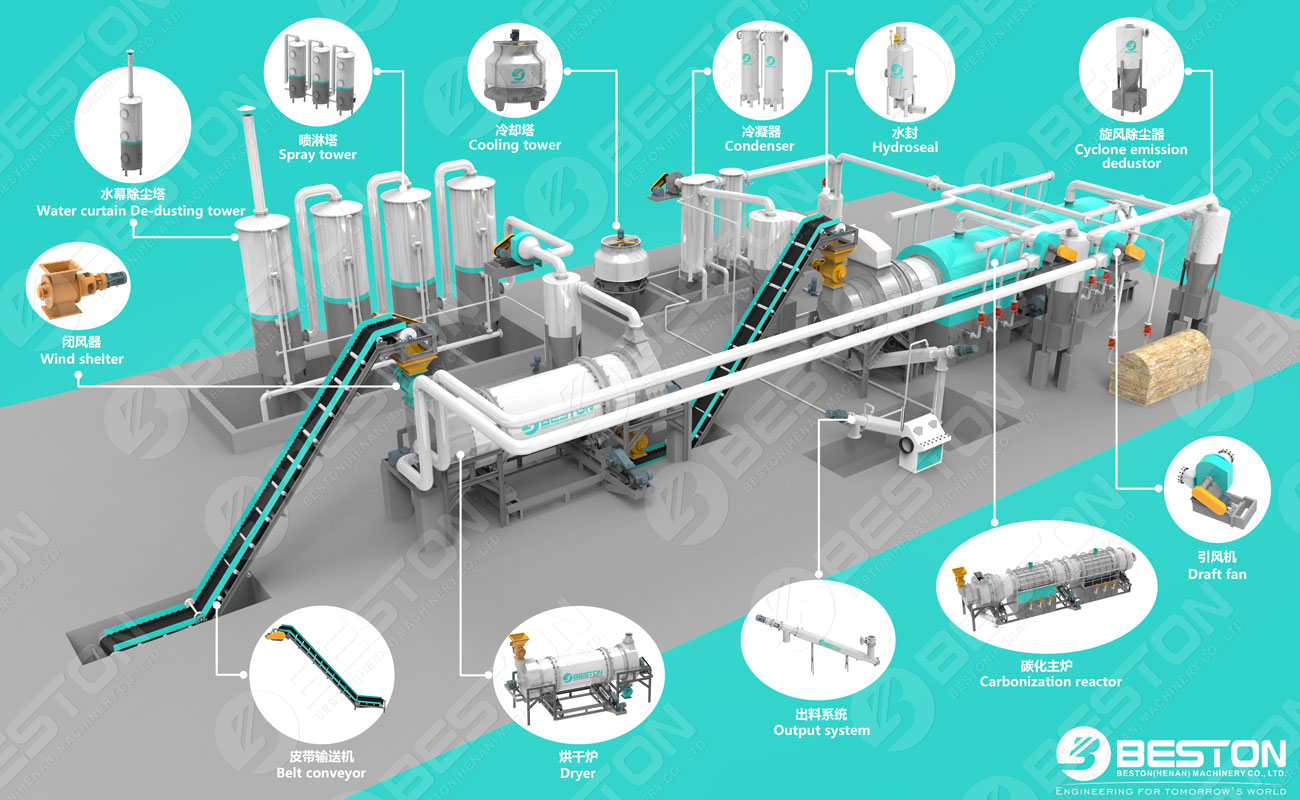

The core of biochar production lies in specialized machinery designed to convert various types of biomass into charred carbon material. A biochar machine for sale typically includes a drying system, feeding system, pyrolysis reactor, condensation unit, and emission control. Each of these components plays a vital role in ensuring efficient and clean production.

Before pyrolysis begins, biomass materials such as wood chips, coconut shells, rice husks, or sawdust must be dried to an appropriate moisture level. Excess moisture can inhibit the heating process and reduce efficiency. Once the feedstock is ready, it is automatically transported into the pyrolysis chamber. The modern design of biochar machines emphasizes energy efficiency, continuous operation, and low emissions, making them an ideal solution for sustainable waste-to-energy projects.

The Core of Biochar Formation: The Reactor

The heart of any biochar production system is the reactor — where the real transformation happens. The biochar pyrolysis reactor operates under oxygen-limited conditions to decompose biomass thermally. This means the material is heated without direct combustion, which allows volatile gases and tars to separate while solid carbon remains as biochar.

Inside the reactor, the temperature typically ranges from 400°C to 600°C, depending on the desired properties of the final product. Lower temperatures yield biochar with higher volatile content, suitable for soil enrichment, while higher temperatures produce more stable char ideal for carbon sequestration. The design of the reactor affects the efficiency of heat transfer and the uniformity of carbonization. Rotary kilns, horizontal reactors, and continuous screw-type systems are among the most popular designs used in modern pyrolysis facilities.

During the heating process, the organic compounds within biomass break down into gases such as CO, CH₄, and H₂, as well as liquid by-products like bio-oil and tar. These gases can be captured and reused as fuel to sustain the process, making the operation nearly self-sufficient in energy. This closed-loop system minimizes external energy input and reduces overall emissions — one of the biggest advantages of pyrolysis-based biochar production.

Integration into the Pyrolysis Plant System

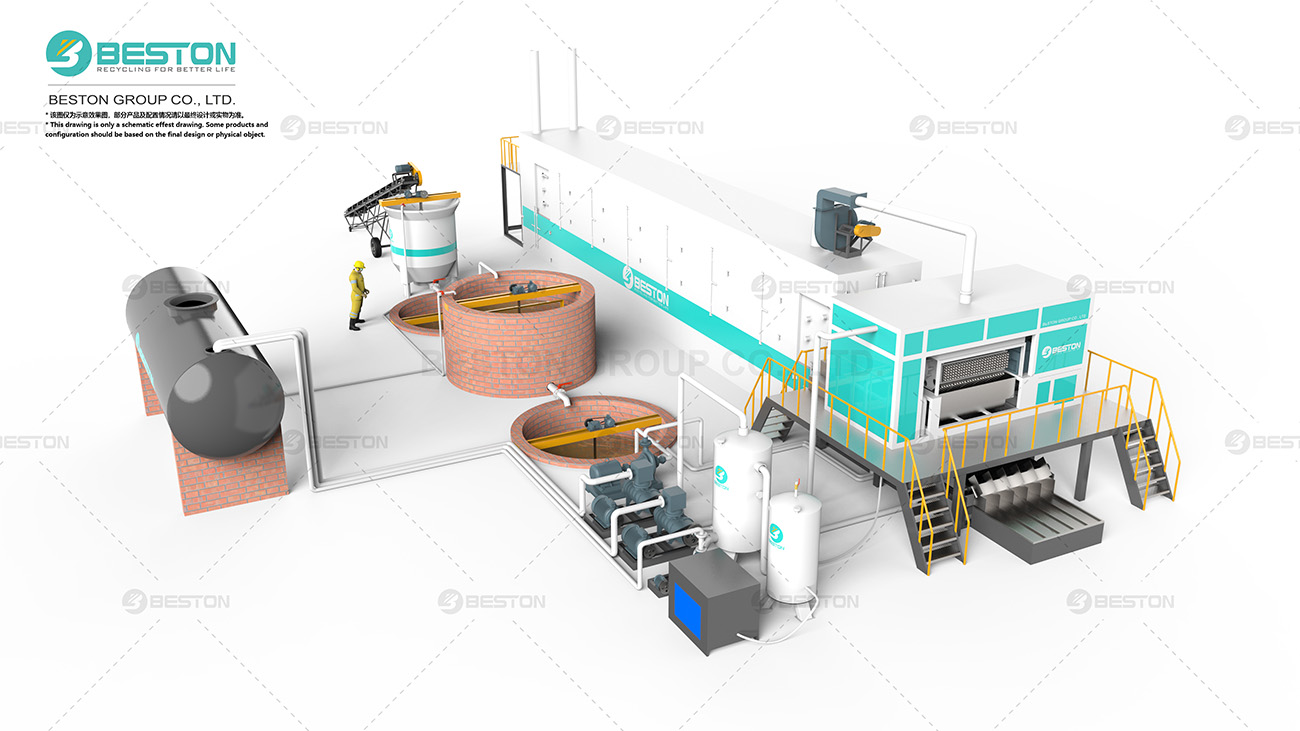

A biochar machine is not a standalone device; it operates as part of a broader pyrolysis plant system. These plants are designed to handle multiple waste streams — including plastics, tires, and organic biomass — converting them into valuable products such as biochar, bio-oil, and syngas.

Within a full-scale pyrolysis plant, the biochar machine works in tandem with waste sorting systems, condensers, gas cleaning units, and emission control equipment. This integration allows for simultaneous management of various waste types, optimizing both resource recovery and environmental performance. The automation and digital monitoring systems integrated into modern plants enable precise control over temperature, pressure, and gas flow — ensuring consistent output quality and operational safety.

Moreover, the scalability of pyrolysis technology means it can serve different industries. Small-scale setups are ideal for agricultural cooperatives or rural communities seeking to process crop residues, while large industrial pyrolysis plants are capable of managing municipal waste on a commercial scale. In both cases, the principle remains the same — converting waste into energy and carbon-rich materials that support sustainability goals.

Environmental and Economic Benefits of Biochar Production

The environmental significance of biochar production extends beyond its ability to sequester carbon. When added to soil, biochar improves water retention, nutrient availability, and microbial activity. This makes it an excellent amendment for degraded or sandy soils. Farmers have reported improved crop yields and reduced fertilizer requirements after incorporating biochar into their agricultural practices.

Economically, biochar projects create opportunities for waste valorization and circular economy initiatives. Municipalities and companies that generate large amounts of organic waste can reduce landfill dependence and generate renewable energy simultaneously. As global attention on carbon markets and sustainability certifications grows, biochar production presents an attractive investment opportunity for businesses aiming to reduce their carbon footprint.

Conclusion

The process of biochar generation through pyrolysis represents a fusion of environmental responsibility and technological innovation. From the efficient operation of biochar machines to the intricate function of reactors within pyrolysis plants, each step contributes to a cleaner and more sustainable future. As global industries and agricultural sectors seek carbon-negative solutions, biochar stands out as a practical and proven method to close the carbon cycle — transforming waste into a valuable, lasting resource. Feel free to reach out to Beston Group for more information.